Best Architectural Uses for Unipavers and Pavement Tiles

In modern architecture, outdoor surfaces are no longer just functional—they are a key part of visual identity, sustainability, and user experience. Unipavers and pavement tiles have emerged as versatile design elements that balance durability with aesthetics, making them a preferred choice for architects, planners, and developers.

From residential landscapes to large urban projects, here’s a look at the best architectural uses for unipavers and pavement tiles.

1. Parking Areas & Driveways

Unipavers are ideal for being used in driveways due to their high load-bearing capacity and resistance to wear. Unlike traditional concrete blocks, they distribute weight evenly, reducing the risk of cracking in the structure. Architecturally, they offer flexibility in patterns, textures, and colors—allowing driveways to complement the overall façade of a building.

For parking areas in residential complexes or commercial developments, pavement tiles can be used to create organized, visually appealing layouts while ensuring long-term durability.

2. Pedestrian Paths & Walkways

Walkways are transition spaces connecting buildings with nature and movement. Pavement tiles provide a clean, uniform surface that enhances safety and accessibility. Architects often use contrasting colors or patterns to subtly guide flow of pedestrians, define zones, or highlight entrances.

In urban projects, Unipavers also support easy maintenance—individual units can be replaced without disrupting the entire pathway.

3. Open-to-Sky Spaces & Courtyards

Courtyards are focal points in residential and commercial architecture. Using Unipavers or decorative pavement tiles here adds texture and rhythm to open spaces. Patterns such as herringbone, basket weave, or geometric layouts elevate the visual appeal; all while maintaining a grounded, earthy feel.

These surfaces also perform well in outdoor conditions, making them suitable for semi-open spaces exposed to sun and rain.

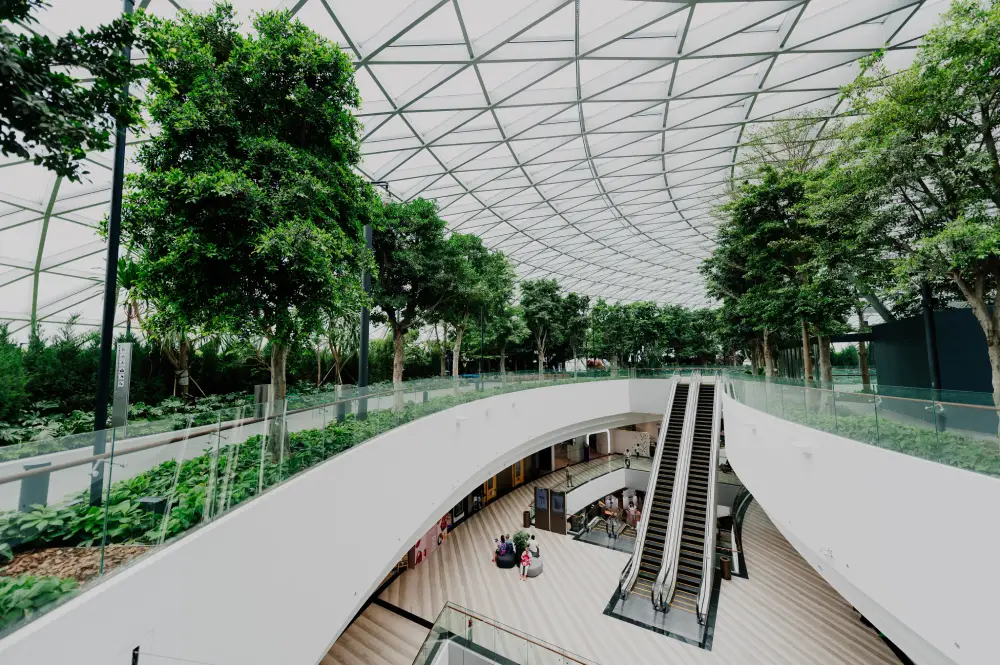

4. Rooftop Terraces and Podium Levels

As vertical living is gaining popularity, rooftops and podium decks are becoming active social spaces. Lightweight pavement tiles designed for elevated areas are now also being used to create walkable, elegant surfaces without overloading the structure. Architects often pair neutral-toned tiles with greenery, seating, and pergolas to design inviting rooftop environments for relaxation and gatherings.

5. Garden Paths & Landscape Design

Unipavers play a major role in landscape architecture. Garden paths, seating zones, and transitional areas benefit from textured Unipavers that blend seamlessly with grass, gravel, and planting beds.

Permeable Unipavers are especially valuable in sustainable design, as they allow rainwater to seep through the surface, reducing runoff and supporting natural drainage.

6. Entry Forecourts & Commercial Plazas

First impressions matter in commercial architecture. Pavement tiles are frequently used in entry plazas, forecourts, and drop-off zones to create a strong visual statement. Large-format tiles offer a contemporary look, while patterned Unipavers add character and depth to expansive outdoor areas.

These materials also withstand heavy foot traffic, making them suitable for malls, offices, hospitals, and institutional buildings.

7. Recreational Areas & Pool Decks

For poolside areas and recreational zones, slip-resistant pavement tiles are a practical and aesthetic choice. Their textured finish enhances safety, while lighter shades help reduce heat absorption. Architects often use these tiles to visually unify pools, decks, and lounge areas into a cohesive design language.

8. Public Spaces & Urban Streetscapes

In urban design, Unipavers are widely used for sidewalks, pedestrian streets, and public squares. Their modular nature allows for creative layouts, easy repairs, and long-term cost efficiency. From heritage zones to modern city developments, pavement tiles help define public spaces that are durable, functional, and visually engaging.

Unipavers and pavement tiles both provide architects with the freedom to design outdoor spaces that are strong, sustainable, and aesthetically refined. Their adaptability across scales—from private residences to large commercial developments—makes them an essential material in contemporary architecture.

When thoughtfully selected and skillfully installed, these surfaces do more than pave the ground—they shape experiences, enhance environments, and elevate the architectural narrative of the nation.