Why High-Quality Raw Materials Matter in Construction

In building, the foundation of every successful project is not just architectural brilliance or engineering expertise, but the materials that are used to turn those plans into reality. Among all the factors that determine the strength, safety, and durability of a structure, quality raw materials are the most important. Whether you’re constructing a residential home, commercial complex, or public infrastructure, using superior building construction materials ensures long-term value, sustainability, and peace of mind.

1. The Backbone of Structural Strength

The strength of any structure lies in the quality of the material used in the construction of that structure. Poor-quality materials may undermine the strength of a structure to withstand load, pressure, and weather conditions. Quality materials have greater tensile strength, compressive strength, and strength. This translates into buildings withstanding natural disasters such as earthquakes, floods, or strong winds with minimal damage.

For instance, high-grade hollow blocks with well-cured aggregates and good-grade cement possess good load-bearing capacity and dimensional stability, hence a good choice for walls and partitions.

2. Safety is Non-Negotiable

Safety comes first in every building project. The buildings built using inferior materials have greater chances of collapsing, causing damage to property, injury, and death. Superior-quality materials go a long way towards eliminating such dangers by guaranteeing the strength of the structure in handling diverse stress situations.

When building construction materials meet regulation standards and quality controls, they also make it simpler to pass inspection and be in compliance with building codes—a very important aspect of being in conformity with the law as well as protecting users.

3. Cost-Effectiveness in the Long Run

Among the common myths is that lower-cost materials decrease the cost of a project. In reality, poor-quality materials can result in higher costs for repairs, premature deterioration of the building, and more maintenance costs in the future.

Expensive raw materials are costly initially, but they last longer and give superior performance, which saves on the cost of ownership later. For example, high-density hollow blocks minimize structural load and energy consumption due to their insulation features, resulting in savings on construction and operation.

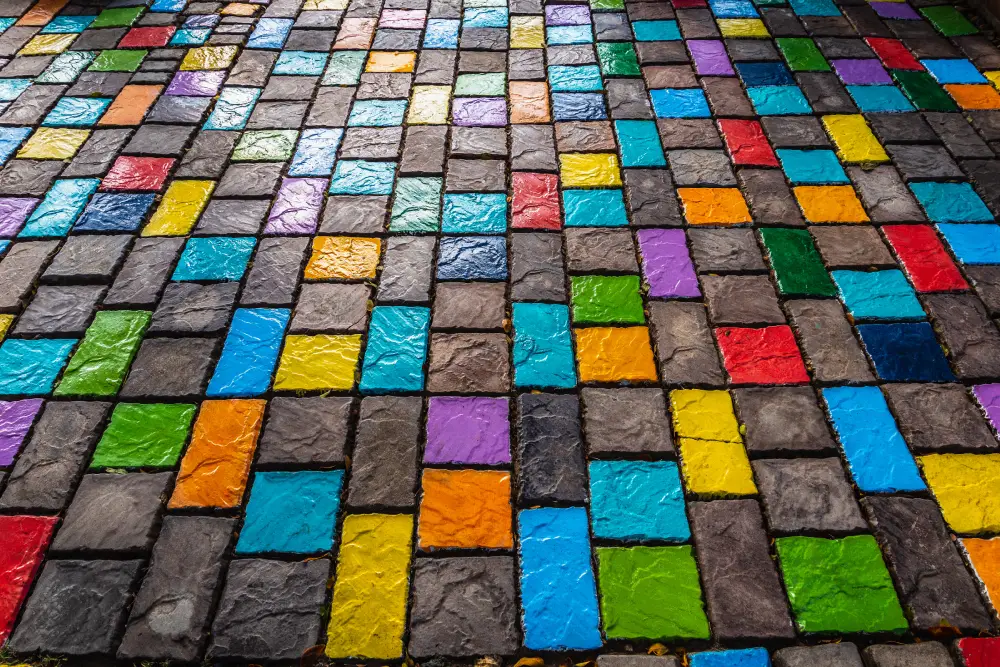

4. Aesthetic and Finishing Excellence

Beyond structural integrity, high-quality materials also contribute to the aesthetics and finish of a building. Smooth textures, consistent color, and uniform shapes result in a polished, professional appearance. Finishing work—like plastering, painting, or tiling—is significantly easier and more effective when the base materials are of high standard.

Quality hollow blocks, for example, provide a neat and precise framework that reduces the need for excessive plaster, minimizing both cost and time in the finishing stages.

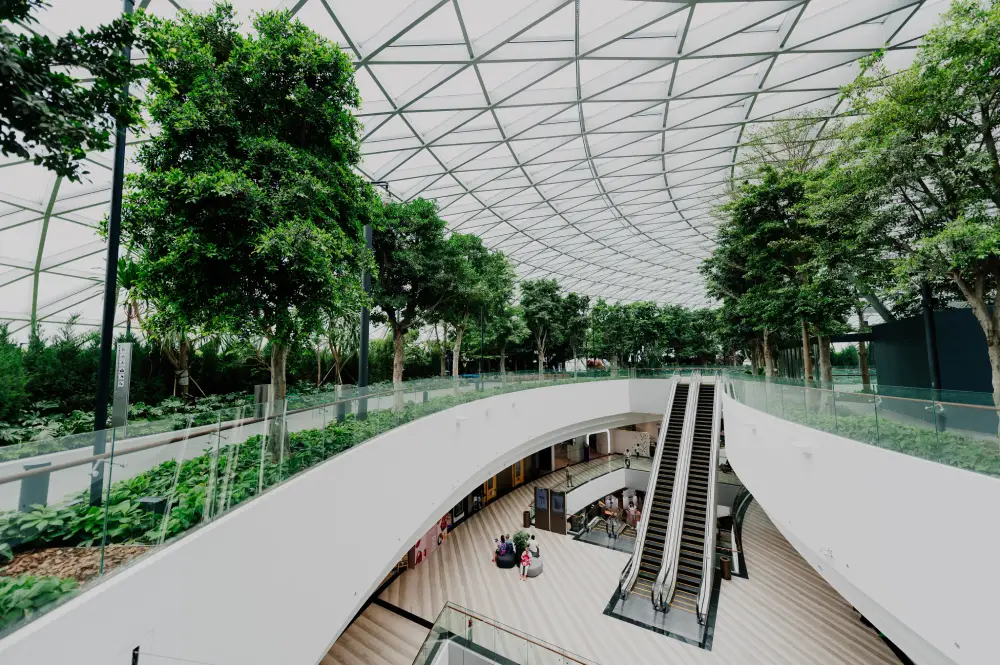

5. Sustainability and Environmental Impact

In an age where sustainability has become a global priority, the choice of construction materials plays a significant role in reducing the carbon footprint of buildings. Eco-friendly materials made through energy-efficient processes and incorporating recycled content are now widely available.

High-quality building construction materials, such as hollow blocks manufactured in controlled environments using modern techniques, not only consume less cement and water but also produce less waste. These materials also enhance energy efficiency in buildings by offering better insulation, contributing to lower energy consumption.

6. Time-Saving During Construction

Projects often face delays due to material failures, inconsistencies, or the need for rework. High-quality raw materials are standardized and perform predictably, which leads to smoother workflows, quicker installations, and fewer onsite issues. This efficiency not only keeps the project on schedule but also reduces labor costs.

For instance, factory-made hollow blocks ensure consistency in size and strength, allowing masons to work faster and achieve uniform walls with minimal adjustment.

7. Market Value Appreciation

A building constructed with quality materials has a higher market value by default. Whether you are planning to sell, lease, or rent the building, clients and tenants will tend to choose a building that promises durability, safety, and low maintenance. Real estate agents also like to advertise houses constructed with dependable, high-quality materials.

Additionally, if the building is certified with LEED (Leadership in Energy and Environmental Design), which are typically materials of high quality, it even increases the property’s authenticity and resale value.

8. Case in Point: The Use of Hollow Blocks

Hollow blocks are a perfect example of how quality building materials can alter the outcome of construction. In comparison with regular bricks, hollow blocks are larger in dimension, which reduces joints and enhances the speed of construction. Their hollow cavities provide great heat and sound insulation, increasing the comfort of interiors.

If produced by better raw materials in quality-checked factories, such blocks are even more efficient, durable, and eco-friendly. Larger-scale builders and construction companies now produce hollow blocks themselves to ensure an equal quality level and accessibility, underscoring their position as a central element in contemporary construction.

At the core of every long-lasting, beautiful, and functional building is a foundation of quality raw materials. From ensuring structural soundness and safety to optimizing aesthetics and sustainability, the importance of high-quality building construction materials cannot be overstated.

While the market may offer a multitude of choices, discerning builders, architects, and homeowners know that compromises in raw materials can have permanent consequences. Spending on quality materials like hollow blocks, high-strength cement, and laboratory-tested aggregates is therefore not a choice but a responsibility.